A substantial revision of the performance Standard from Europe in the shape of EN 124-5:2015 has provided a clear framework for composite manufacturers like EJ to adhere to and confirms that composites are here to stay. Paul Smith, managing director of EJ in the UK, explains.

When it comes to manhole covers and access solutions, we are seeing composite access covers being used today more and more frequently for a wide range of applications, from the construction to the aerospace industry. This is mainly due to the many benefits that high-quality composite products offer, such as their ease of handling, resistance to corrosion, non-conductivity and zero resale value.

The arrival of composite access covers to the market has delivered new advantages and a new level of choice for project managers of utilities and municipalities, engineers, specifiers and clients. A substantial revision of the European performance Standard in the shape of EN 124-5:2015 has provided a clear framework for composite producers to adhere to. This latest EN 124 Standard is the first to define detailed performance requirements for composite access covers, as the previous 1994 edition of the Standard did not, confirming that composites are here to stay.

Whilst composite products offer many advantages, how composite products are made and the Standards they are produced to can vary widely, resulting in low quality products entering the market. Given the potential for such a variety of products within a material scope, it is important that stringent material performance requirements are in place, and this is the primary reason why the European Standard EN124 was expanded with dedicated material annexes, such as Part 5 for composite access covers.

The testing requirements in this new Standard include such aspects as;

- Full load and permanent set testing.

- Fatigue testing.

- Resistance to moisture and fuel absorption.

- Impact resistance.

- Low temperature embrittlement.

- UV weathering resistance.

- Slip/skid resistance.

All of which are known issues relating to composite cover failure, outlining the importance of the performance requirements of both product certification and high-quality manufacture – to reduce risk and to provide peace-of-mind to buyers and end users.

CEN (The European Standards-making authority) have acknowledged the potential risks to the market of uncertified or non-compliant products purporting to conform to EN124. Their advice to European certification bodies is to develop and provide certification schemes for manufacturers so that products can be built, verified and certified to the latest EN124 Standard. Third party certified products represent the maximum reduction of this potential risk and therefore fulfil the obligation to provide safe products and provide the reassurance of managing liability.

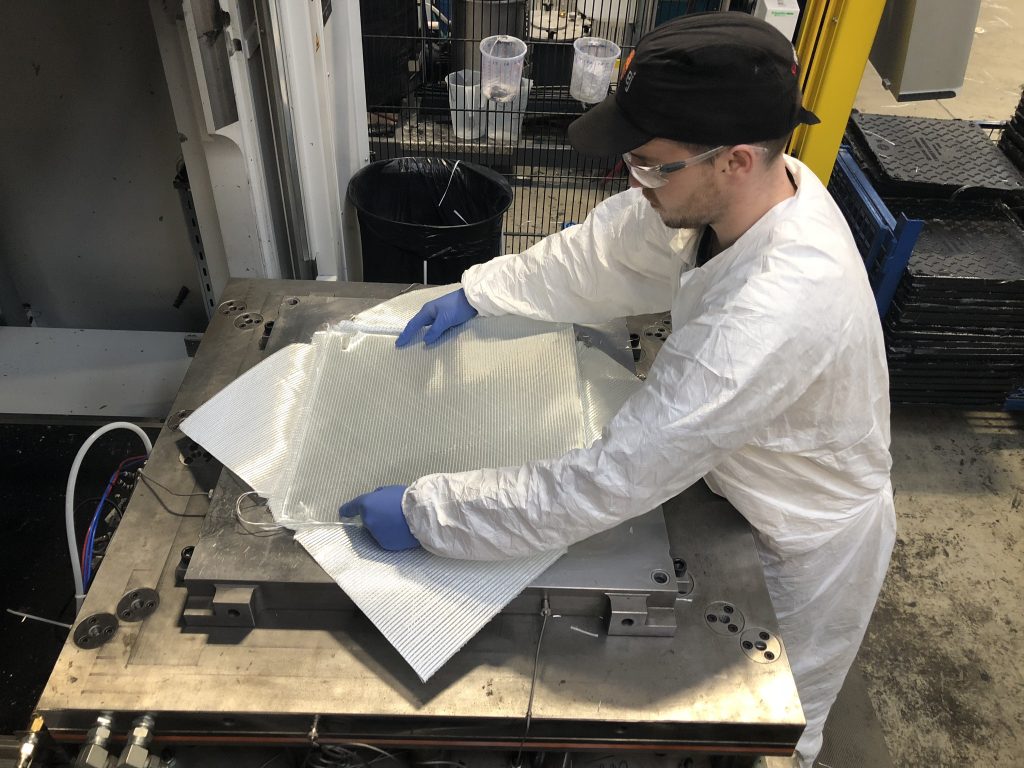

To meet the stringent requirements withinEN124-5:2015,EJ(the world leaderin the design, manufacture and distribution of access solutions), have developed the IDS ELITE, a high-performance, brand-new composite access cover, and the first and only composite cover and frame on the market that is fully third party certified to BS EN 124-5:2015. Manufactured using a different moulding technique called RTM, its engineered structure also means that there is a weight-saving of up to 60%, providing enhanced safety and environmental benefits over traditional products.

To support the above, the EJ IDS ELITE and its production process controls are independently tested, verified and accredited by the NSAI and carry their certification mark. As industry leaders, EJ commissioned extensive research and testing to drive innovation, demonstrate their commitment to the European Standard and create product excellence.

https://www.ejco.com/em/en/resource-center/product-briefs/composite-access-covers-and-en-124-2015