Perforated metal in modern architecture

The creative use of perforated metal in urban design shapes the framework of our surroundings. Perforated metal offers a whole new level of freedom for designers and architects who want to influence the cityscape of tomorrow and breathe new life into urban areas.

As any architect can testify, a city is not just about the buildings. The city is a landscape of aesthetics, emotions and ambitions. The city is an expression of human interaction and a crossroad of past, present and future. This makes the urban landscape a playground for ambitious architects and entrepreneurs who want to make their mark and to influence the shape of tomorrow.

Architects focus on new ways to design modern buildings and are on the look-out for materials that will contribute to their interpretation of city life. RMIG is a world specialist in perforated metal and leads the way in developing innovative solutions for creative urban design that are based on perforation in all shapes, sizes, colours and surfaces.

The Music Box MSCP

Multi-storey car park, Hayes, Middlesex, England

Architects: Studio Egret West

Music history brought to life with RMIG ImagePerf

The Fab Four sang “Baby, you can drive my car…”, and they would probably love to drive it into the multi-storey car park in Hayes, England, where a facade created from RMIG ImagePerf brings to life the famous photo of screaming fans at a Beatles concert.

Over 1,000 perforated sheets were manufactured and supplied by RMIG for the project. The technology used for RMIG ImagePerf made it possible for this iconic photograph to be reproduced using various hole sizes. The sheets were subsequently powder coated, making them weather resistant and ensuring that this amazing image will be enjoyed for many years to come.

Technical characteristics

Raw material: Sendzimir galvanised steel

Pattern: RMIG ImagePerf

Thickness: 2.5 mm

Finishing operations: Bending

Surface treatment: Powder coating

MSCP Queen Elizabeth Olympic Park

Multi storey car park, London

Architects: Haptic Architects

Recladding of a multi storey car park

Over 1,000 high quality perforated aluminium sheets from RMIG were used for Haptic Architect’s competition winning scheme for the recladding of a multi storey car park. The triangular perforated sheets have been powder coated with four different shades of silver to intensify the three-dimensionality of the facade, giving it a contemporary feel. The positioning of the panels creates an ever-changing pattern of light and shadow.

Technical characteristics

Raw material: Aluminium 1050

Pattern: LR20x110U120x132

Thickness: 3.0 mm

Surface treatment: Powder coating

MSCP Time Square, Bridge Street

Multi-storey car park, Warrington, England

Architects: Leach Rhodes Walker

A facade of perforated sheets used for a state-of-the-art facility

As part of the redevelopment of Bridge Street in Warrington, Cheshire, a multi-storey car park has been constructed, providing the town with more than 1,000 muchneeded parking spaces. This massive eightstorey car park has a remarkable facade made from an astonishing 3,500 m2 of perforated sheets manufactured and supplied by RMIG with RMIG ImagePerf technology being used to create the vivid perforated patterns.

Technical characteristics

Raw material: Aluminium EN 1050 and Aluminium J57S

Pattern: RMIG ImagePerf

Thickness: 3.0 mm

Finishing operations: Folding

Surface treatment: Powder coating and anodising

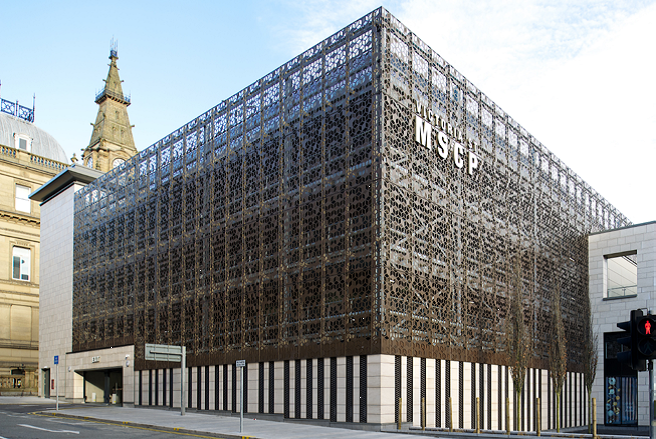

MSCP Victoria Street

Multi-storey car park, Liverpool, England

Architects: Leach Rhodes Walker

Perforated facade helps transform city centre

When designing the facade of the MSCP in Victoria Street, Liverpool, the architects wanted to pay tribute to the city’s fishing industry and decided on a modern interpretation of the fishnet pattern. Thanks to RMIG ImagePerf technology, it was possible to reproduce the design on to the 243 perforated sheets that made up the facade, covering an area of 800 m2.

In addition to the perforated facade cladding, RMIG also supplied expanded metal for the ground leve of the MSCP. Both the perforated sheets and expanded metal provide the necessary ventilation and light for a facility of this kind.

Technical characteristics

Raw material: Aluminium

Pattern: RMIG ImagePerf

Thickness: 3.0 mm

Finishing operations: Folding and cutting

Surface treatment: Powder coat